I thought since it’s been exactly a year since I upgraded my Giant Explore E+ to a Rohloff Speedhub 500/14 internal gear hub, that it’s a good time for an update. As for stats: I have put 5,180+ miles on this bike since the conversion.

A custom 3D-printed speed sensor mount

One of the items left unfinished with my initial upgrade to the Rohloff was mounting the speed sensor, which I initially left attached using a hand-cut piece of foam, some zip ties, and some tape:

I initially intended to make a custom mount for it with my 3D printer, and recently got the 3D printer out of storage and set it up, modeled the part, and made it. It’s held on with (beefier) zip ties and double sided adhesive foam mounting tape. It looks great and is working very nicely, no longer getting shifted and out of line with the spoke magnet:

First failure: Worn Rohloff input sprocket

After several thousand miles, I noticed the chain was “skipping” under load, and after swapping chains it was still occurring. I took things apart and noticed that the input sprocket to the Rohloff was fairly worn. I put the bike through a lot towing heavy trailers up big hills, so I am not too surprised by this:

This was a 14T sprocket, and I already had 15T and 16T sprockets on hand, so I decided to install a 15T sprocket instead, as I could use the even-lower gearing and didn’t need all the top-end in high gear. You can see the comparison between sprockets here:

The swap completely resolved the skipping issues, and I am really liking the even-lower low gear.

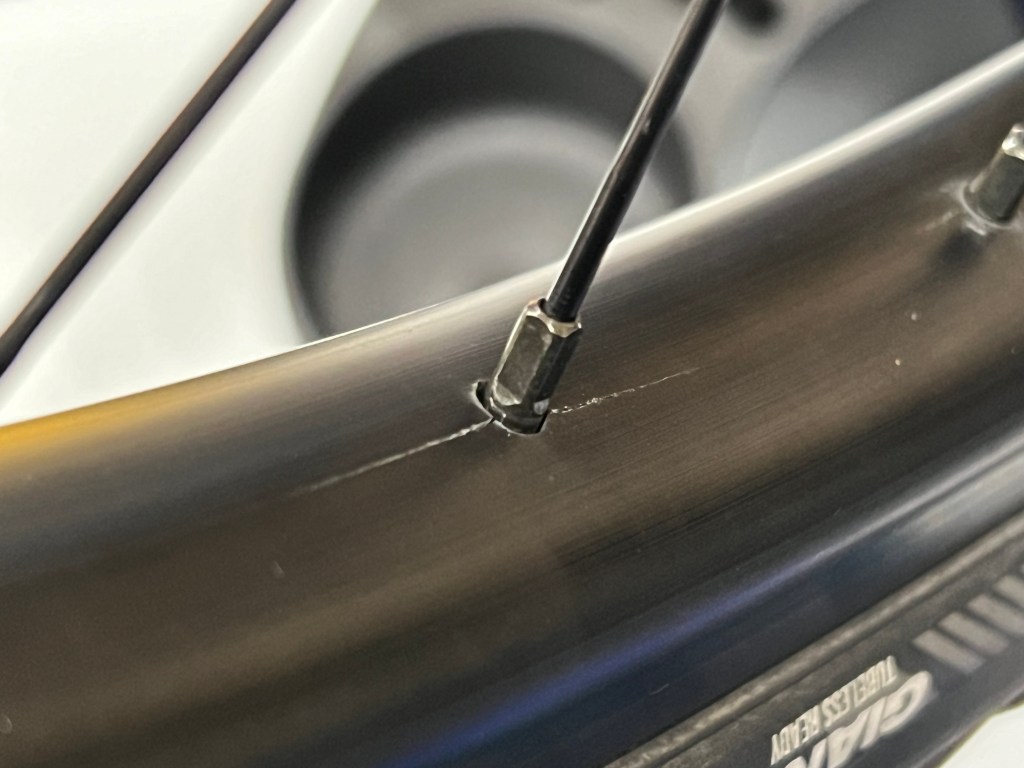

Second failure: Cracks in the Velocity Cliffhanger rim

The biggest failure I had was a failure of the rim at 4,400 miles, with many spoke holes cracking, enough to ultimately lose all spoke tension:

I ended up rebuilding the wheel (at home this time) on another new Cliffhanger rim identical to the first.

What remains to be done

Not much, really! I still haven’t bothered to shorten the shifter cables, but doing so would probably make shifting a little easier by reducing friction. I’ll probably do that soon.

Conclusion

This was an excellent upgrade. While the implementation is not perfect (it could be better with a bike designed around the Rohloff), it works great. Performance-wise, it’s the best possible upgrade for this bike. I am in love with it.